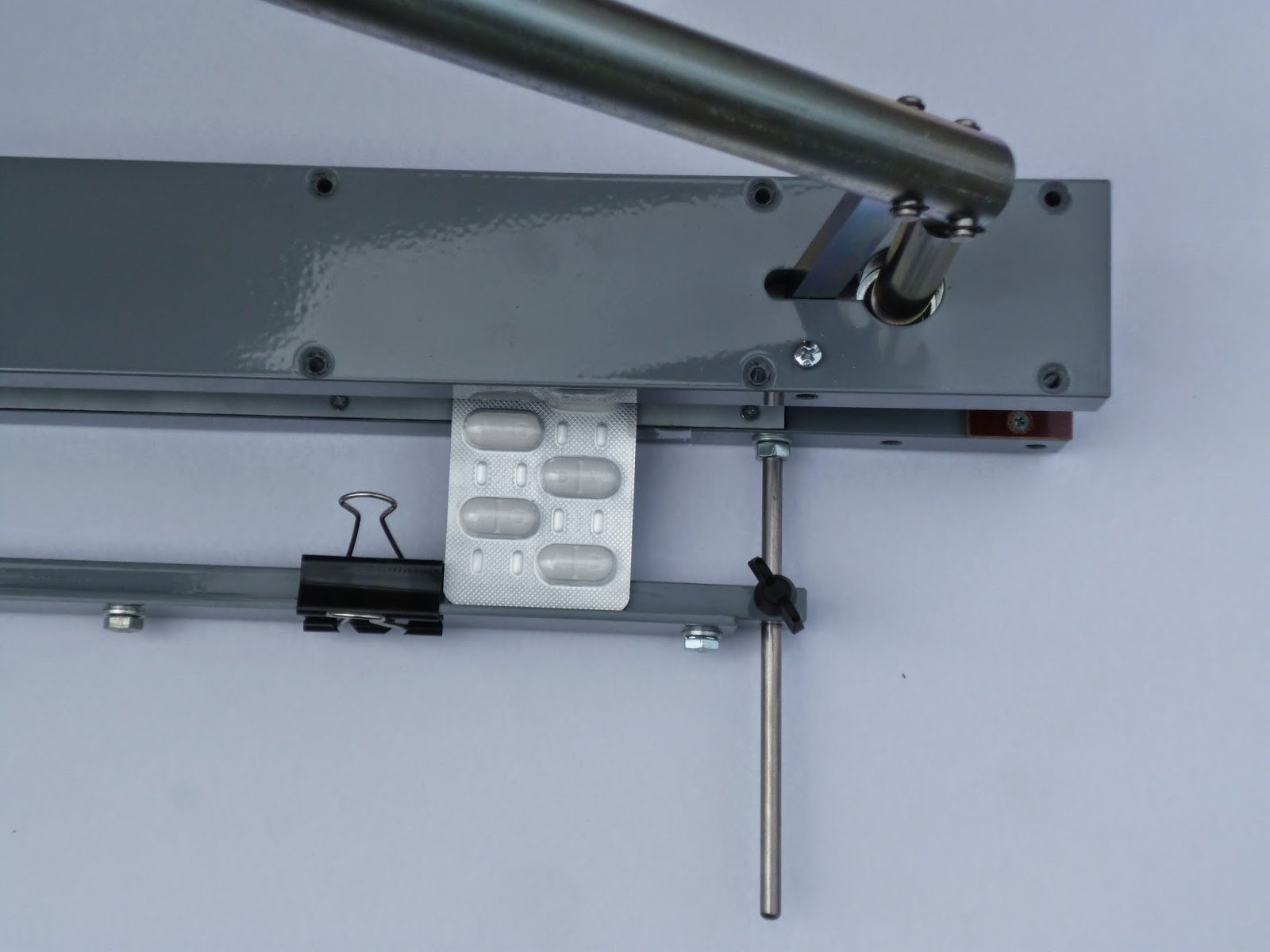

We had to modify the Paperfox HH-1 return receipt making machine to be able to use lighter paper and to be able to stick double sided self adhesive strips on booth side or just on one side of the paper.

So we equipped the Paperfox HH-1 return receipt making machine with an additional set of guiding rollers to ensure a straight pass through of the paper even if the machine applies adhesive tape only on one side.

In addition to the normal shut off valve, we installed an other manual valve to switch off one of the TD-1 tape applicator heads if it is not needed.

The other parameters of the device are didn't changed. The Paperfox HH-1 return receipt making machine can handle two rolls of 6...12mm wide "finger lift" double sided selfe adhesive rolls. The inner core diameter is 76mm the maximal external diameter of the rolls is 300mm.

The Paperfox HH-1 return receipt making machine has a counter to count the sheets processed. you can set the position of the tape application roughly with the position of the optosensor, and finely vith the manual pneumatic valves on the pneumatic cylinders.

The upper valve sets the start position of the tape lying (if you close the upper valve then the distance of the tape start position increases from the sheet edge) the lower valve sets the end position ((if you close the lower valve then the end position getting closer to the back side of the paper).

There is no English operational manual at this moment about this device, but you can find more information in the TD-1 tape applicator operational manual.